Coatings Technology Blog

Lectrofluor® Gives Stainless Steel Condensate Pumps Extra Protection Against Corrosion

When it comes to ensuring the reliability of pharmaceutical manufacturing machinery, mitigating the effects of frequent washdowns and the threat of corrosion are part of the territory. Although stainless steel is a common material for parts and machines throughout the industry thanks to its corrosion resistance, not every stainless steel alloy can resist corrosion when exposed to certain chemicals or conditions.

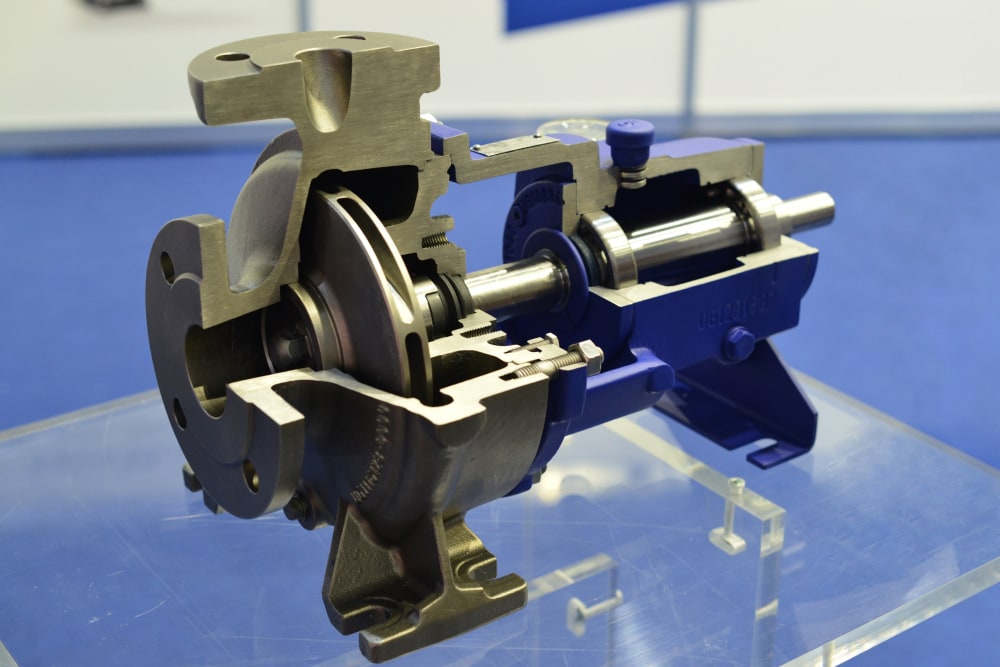

For example, a pharmaceutical injectables manufacturer was experiencing corrosion problems in production equipment. Its facilities engineering manager contacted us about a stainless steel condensate pump housing and cover assembly that undergoes a standard cleaning and maintenance cycle. Maintenance personnel sometimes added a chlorine-based cleaning solution but at other times used an ammonia-based cleaning agent in the company's clean in place (CIP) process. These chemicals caused the stainless steel condensate pump to corrode.

To address the problem, our technical support group recommended Lectrofluor®, which is particularly effective against severe corrosion and chemical attack. Lectrofluor is a polymer-based coating that is well-suited for food and drug manufacturing applications.

Lectrofluor also offers the following features and characteristics:

- USDA and FDA compliance

- Dry lubricity for low coefficient of friction

- Prevents galling

- Heat stability

- Self-lubricating properties for extended wear

- Mold release properties

After several months of successful pump cleaning and maintenance without any recurring corrosion issues, the customer reported that the Lectrofluor-coated pump "looks as good as the day it first arrived coated." After the initial success, the customer sent us another condensate pump for coating. The customer is also planning to upgrade additional production equipment with General Magnaplate surface treatments.

Preventing corrosion of stainless steel parts is not always a straightforward endeavor, especially when harsh, caustic chemicals contact the surfaces. This successful application is another example of how we engineer our surface treatments to provide an effective defense in harsh conditions specific to your application. When you need to protect surfaces against harsh environments, our technical experts stand ready to review your application details and specifications to recommend the most suitable surface treatment.

For more information about our Lectrofluor surface treatments, please visit our product page.