Company History

Our Timeline

From a small garage in Hoboken, New Jersey to our position as a world leader in the science of surface treatments, it’s been a remarkable journey. This timeline traces our 70-plus years of innovations, milestones, exceptional products, employee dedication and Covino family stewardship that have shaped Magnaplate into the proud company we are today.

1952

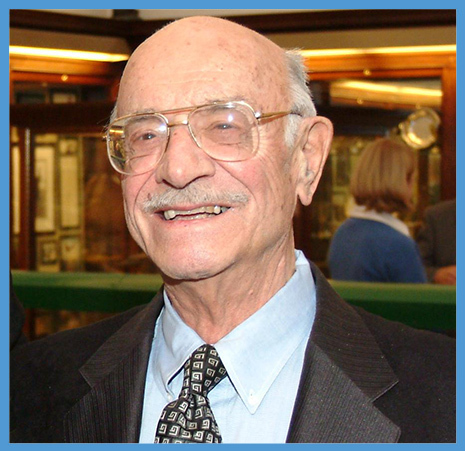

Dr. Charles P. “Doc” Covino establishes Magnaplate Metal Finishers as a non-destructive testing laboratory inside a small, two-car garage in Hoboken, New Jersey. At the time, the aircraft industry had few options for metal testing. Doc saw an opportunity to satisfy this critical need for the growing industry and he also created a variety of metal coatings. Doc’s wife, Sylvia Covino, will join the company in 1959, and together they lay the groundwork for an enduring family business.

1954

Magnaplate begins its steady evolution

The first of many expansions, Magnaplate outgrows its Hoboken garage and opens a more functional facility in Bloomfield, New Jersey. The company’s growth in the 1950s includes a move to Belleville, New Jersey in 1958 and the acquisition of Eastern Testing Labs in 1959.

1958

Magnaplate is there for NASA’s beginning

President Dwight Eisenhower signs the National Aeronautics and Space Act of 1958 into law, and, soon after, Magnaplate is there to help NASA meet its need for a new kind of surface technology that could withstand the harsh outgassing conditions of space. Since then, Magnaplate coatings have been applied on NASA space craft and vehicle components for virtually every mission mission since the beginning of the U.S. space program.

1961

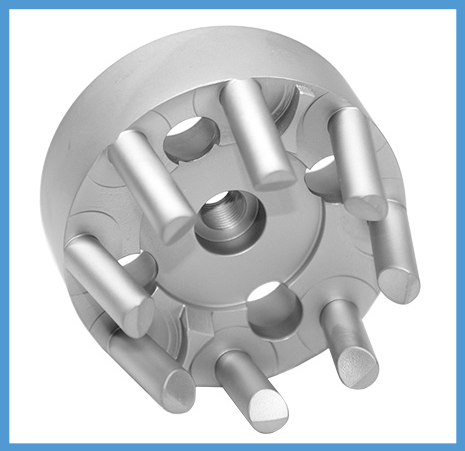

HI-T-LUBE® is invented

This dry-film lubricant solves critical problems like wear, galling and fretting on steel, stainless steel and copper alloys at high and low temperature extremes — even under heavy loads. Since HI-T-LUBE does not outgas in space, it has been a preferred choice in space since the mid-1960s. Aboard fighter planes, HI-T-LUBE solved an afterburner brake pedal jamming issue that had caused a series of accidents.

1962

Doc Covino publishes a groundbreaking QA manual

Doc Covino grows his reputation as an authority on quality assurance with the publication of his groundbreaking Quality Assurance Manual: Procedures and Forms for the Establishment of a Plant-Wide Quality Assurance System, distributed by Industrial Press.

1963

Doc Covino advises NASA on QA

Doc Covino and a handpicked team comprising scientific specialists evaluate all Quality Assurance for NASA and its prime contractors. A report and recommendations are made to the entire NASA staff. This helps establish Doc’s renown as a world-leading metallurgist and plays a major part in the Company’s success.

1964

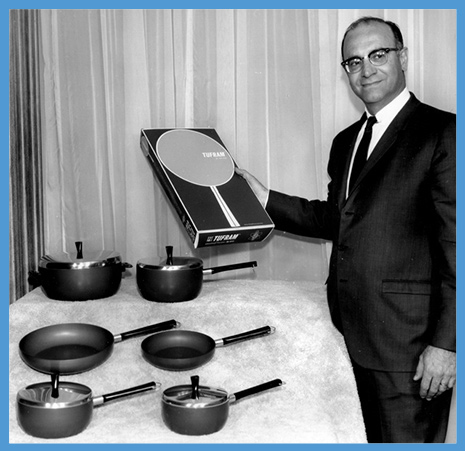

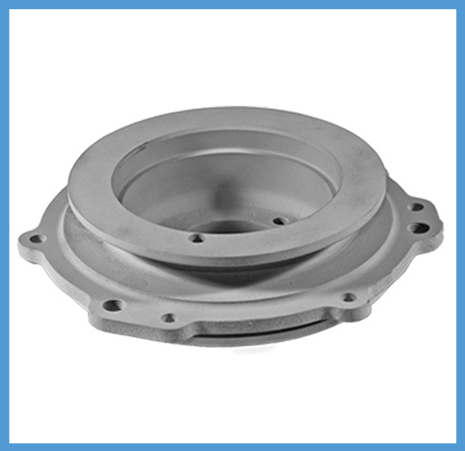

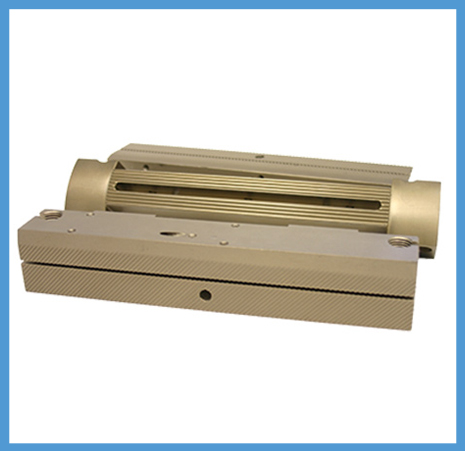

TUFRAM® is invented

TUFRAM satisfies NASA’s need for a coating for aluminum that does not outgas, helping solve critical wear and performance problems on space vehicles. TUFRAM coatings have been widely adopted for aluminum surfaces on all types of manufacturing, processing and packaging equipment.

1967

Magnaplate launches a TUFRAM® cookware line

Thanks to TUFRAM’s® popularity, the company moves to Linden, New Jersey and Tufram, Inc. is formed to produce a line of pots and pans with space-age names. Consumer Reports ranks the Tufram-branded cookware number 1 in the U.S. for two years in a row.

Magnaplate partners with its first licensee

Japan Vacuum Engineering — now Ulvac — becomes Magnaplate’s first licensee. Ulvac and many of our original licensees continue to flourish with us today, including: 1978, FFV (Nordic region. Capabilities now belong to Bodycote); 1987, Poeton Industries (U.K.); 1988, MIFA Surface Treatment (The Netherlands); 2008, SEC Plating (Australia); 2011, Precision Surface Technologies and Aluminum Surface Technologies (Canada), Electrochem (India); 2014, Tecnocrom (Spain); 2018, Poeton Polska.

1968

Magnaplate launches CANADIZE®

Recognizing that titanium is highly susceptible to hydrogen pickup or embrittlement, our metallurgical engineers created CANADIZE — a series of coating processes that would preclude any hydrogen absorption. CANADIZE solves wear, friction, galling, seizing, moisture and corrosion problems in a broad spectrum of applications involving titanium and its alloys.

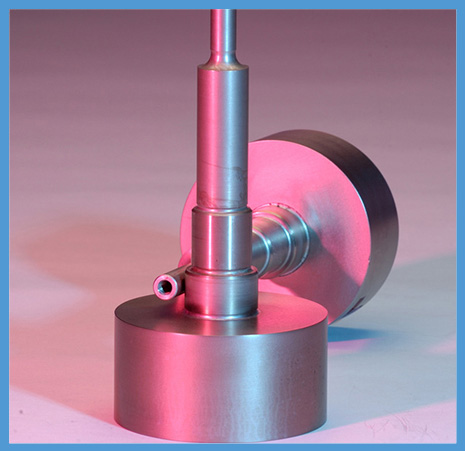

1969

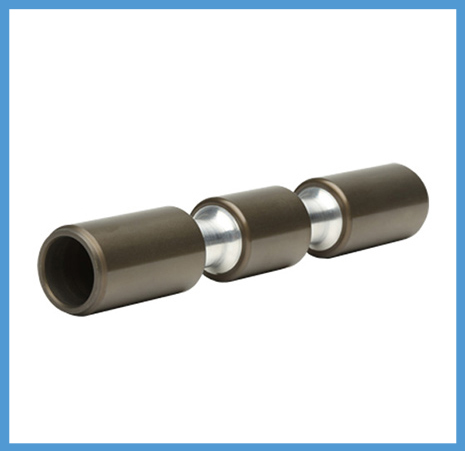

Magnaplate helps take man to the moon aboard Apollo 11

Thanks to Magnaplate, not only was man able to walk on the moon, he was able to drill into it, too. CANADIZE® treatment on both the inside and outside of the titanium core-sample drill tubes prevented galling at the joints and in the drive shaft. It also eliminated the danger of moon rock samples being contaminated by titanium particles.

1970

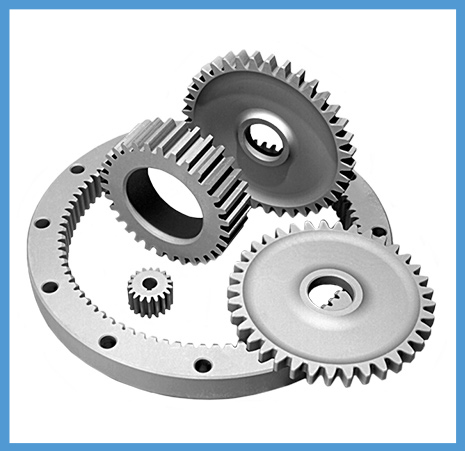

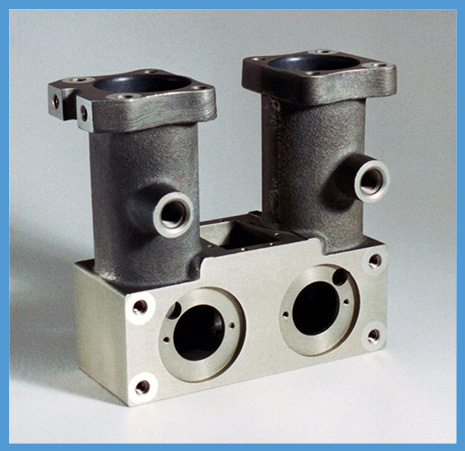

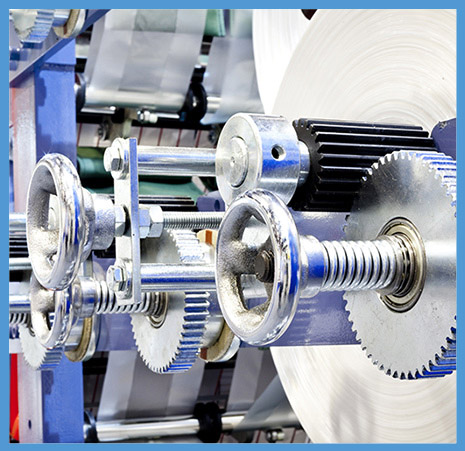

NEDOX® is invented

NEDOX combines the advantages of plating with the controlled infusion of low-friction polymers and dry lubricants to protect most metals — including aluminum — from wear, corrosion, resisting and galling and significantly extend the life and performance of critical components in many industries.

Magnaplate coatings prove invaluable aboard Apollo 13 LEM module

Synergistic coatings protected the fuel-mixing control valve on Apollo 13’s LEM Ascent Engine. When the Command Module was incapacitated, the engine changed the LEM’s trajectory and delivered the astronauts back to Earth.

1973

A moon rock comes to Magnaplate

As a mark of gratitude for his contribution to the space race, NASA presents Doc with a piece of the “rock” which is displayed at Magnaplate’s Linden facility. It is then sent to the Smithsonian for public viewing.

Magnaplate Arrives in The Lone Star State

Magnaplate begins its more than 50-year association with The Lone Star State, opening its first Texas facility in Grand Prairie.

1975

MAGNADIZE® is invented

Developed to excel in harsh vacuum and low-temperature conditions in space, MAGNADIZE increases the surface hardness and lubricity of magnesium, improves the metal’s resistance to corrosion and oxidation and prevents abrasion and galling. These factors allow the aerospace industry, for example, to use magnesium alloys to build lighter, fuel-saving aircraft.

1976

Magnaplate introduces LECTROFLUOR®

These polymer-based surface treatments provide superior corrosion and chemical resistance and mold release, even in extremely hostile environments. Effective at both high and low temperatures, LECTROFLUOR coatings can be applied to mixed metal substrates.

1981

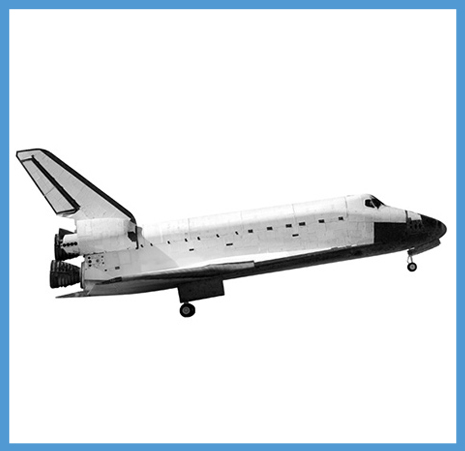

Space shuttle Columbia makes first Earth orbit

As NASA entered more advanced phases of its space program, it turned to Magnaplate's technical expertise to ensure extremely hard, dry-lubricated surfaces for hundreds of aluminum, titanium and steel parts, tools and pieces of equipment.

1982

Howdy, Arlington Texas

Magnaplate upgrades its capabilities and opens a new and future home by moving its Texas operation to its current Arlington location.

A new generation of the Covino family joins the company

The second-generation of the Covino family is ready to help Magnaplate grow and evolve as Candida Aversenti joins the company as Marketing Manager.

1983

MAGNAPLATE HMF® and MAGNAGOLD® are created

The MAGNAPLATE HMF process creates an extremely hard, mirror-smooth, lightly reflective microfinish on the surface of ferrous metal, copper or aluminum alloy components. MAGNAGOLD is an enhanced physical vapor deposition (PVD) titanium nitride coating that protects high-strength alloys against wear and abrasion up to 20 times better than stainless steel.

1985

Magnaplate bolsters its leadership

Edmund Aversenti joins General Magnaplate in 1985 and Candida C. Aversenti becomes President of General Magnaplate in 1986.

1988

MAGNAPLATE HCR® is invented

HCR combines the hardness of aluminum oxide ceramic with the sealing action of metallics and polymers to impart previously unattainable levels of hardness, corrosion resistance and permanent lubricity to aluminum and aluminum alloy parts.

1989

PLASMADIZE® is introduced

Combining the advantages of thermal spraying with the controlled infusion of polymers, dry lubricants or other materials to provide an entirely new composite and improved properties, PLASMADIZE is particularly attractive as a cost-effective coating for very large surfaces or parts.

1990

Magnaplate launches DYNALOY®

Able to withstand high temperatures while maintaining design tolerances, DYNALOY is a hard, super-thin, selectively deposited chromium coating specially developed to create a micro-surface that aids in lubricant dispersion and to eliminate friction over a wide range of applications and environments.

1991

Doc receives a prestigious honor in his home state

Doc receives the Inventor of the Year award from the New Jersey Inventors Hall of Fame (NJIHoF), an organization formed to “honor inventors, organizations and others who have contributed to innovation in New Jersey.” Other notable inventors honored by the NJIHoF include Thomas Edison and Albert Einstein.

1992

The accolades keep coming

Magnaplate continues to earn accolades, being presented with The Lyndon B. Johnson Space Center Award for our outstanding contributions to the space program. The relationship between NASA and Magnaplate dates back to the agency’s founding in 1958.

1995

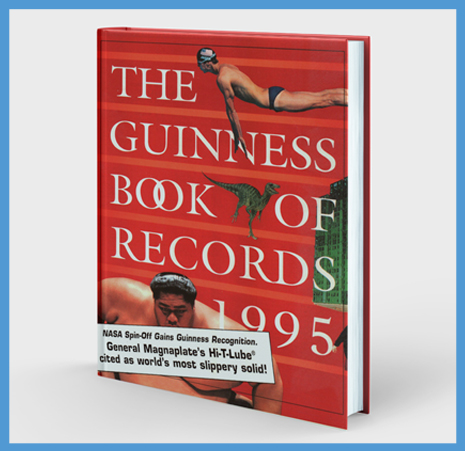

HI-T-LUBE® is listed in the Guinness Book of World Records

HI-T-LUBE earns a Guinness Book of World Records recognition as the solid with the lowest coefficient of friction (COF) in the world — 0.03 — replacing Teflon as the record holder for “world’s slipperiest solid.”

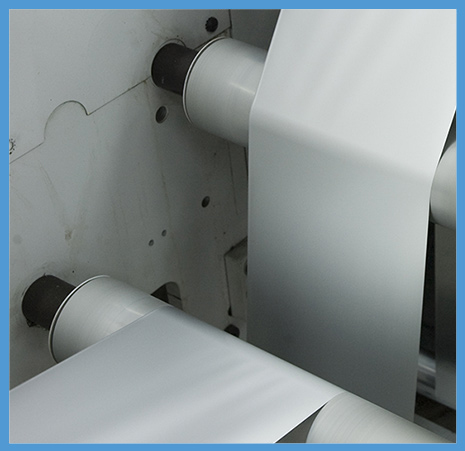

MAGNAPLATE TNS™ is invented

TNS solves the “sticky substance” problems encountered so often in all segments of the adhesive industry, including adhesive formulating, label printing, tape manufacturing and converting.

1996

Magnaplate.com goes live

Magnaplate.com puts the company firmly into the cyber age and has since provided a wealth of information about its products and how they can be successfully applied to metal surfaces and other substrates.

GOLDENEDGE® is invented

GOLDENEDGE is an ultra-hard, micro-thin coating that is ideal for use on the cutting edges of blades, knives, slicers and other sharp-edged devices and can maintain sharpness up to 20 times longer than other coatings.

1999

More honors in New Jersey

Magnaplate is once again recognized by the New Jersey Inventors Hall of Fame. This time, the company wins the organization’s Corporate Award, which honors companies that “have created and successfully commercialized products of great significance and enduring impact to the lives of humans worldwide.”

A magnificent career

After 49 years of guiding Magnaplate in providing high-quality surface treatments for protecting metal surfaces and other substrates across many industries, Doc Covino retires as CEO of Magnaplate.

2000

Magnaplate’s Linden, New Jersey facility recognized by OSHA

Magnaplate’s Linden, New Jersey facility receives VPP “Star Site” designation from OSHA. Star Site is the highest designation given by OSHA, and it makes Magnaplate one of the only “small” companies in the United States to receive this honor. OSHA’s Star Program is “designed for exemplary worksites with comprehensive, successful safety and health management systems.“

2002

General Magnaplate turns 50

Magnaplate celebrates its 50th anniversary of producing quality, high-performance surface treatments that protect vital components in many industries against harsh and damaging conditions.

2004

Magnaplate goes to Mars

A special high-friction version of PLASMADIZE prevented Kevlar rope on the Mars Spirit Rover’s descent rate limiter from slipping. Thanks to the increased friction enabled by PLASMADIZE, NASA was able to successfully land the Spirit Rover on Mars.

2006

Magnaplate’s Arlington, Texas facility receives ISO 9001:2000 certification

After undergoing very strict audits, General Magnaplate’s Arlington, Texas facility earned its ISO 9001:2000 certification. This internationally recognized standard signifies that General Magnaplate consistently provides the highest level of coating quality possible by applying a prescribed quality management system. Magnaplate proudly continues to earn subsequent ISO 9001:2015 recertifications.

The Magnaplate board redoubles its guidance and leadership

Dr. Charles P. Covino, the Company’s founder and Chairman of the Board, is elected Chairman Emeritus, and Candida C. Aversenti is elected Chairperson.

2007

A great loss

Dr. Charles P. Covino, founder of General Magnaplate, passes away at the age of 83. However, his spirit of innovation and determination is alive and well and continues to flourish.

2008

General Magnaplate makes changes to its executive leadership

Candida C. Aversenti is named CEO and Board Chair, and Ed Aversenti is appointed President and COO. With these elevations, the company is poised for future growth and innovation.

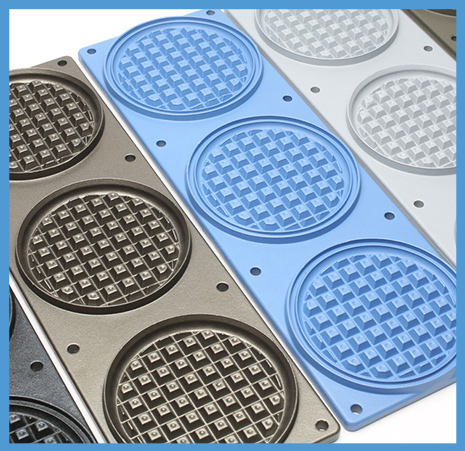

2011

Magnaplate 10K™, a release coating for high-heat applications, is introduced

The 10K family of coatings gives parts excellent release properties at high temperatures, resists abrasion and exhibits excellent hydrophobic properties, allowing for easy cleanup. 10K can be applied to many popular Magnaplate Coatings, is free of PFAS and complies with FDA regulations.

2014

NEDOX® PF-F is developed

This nickel composite coating ensures high-temperature performance without polymers or dry lubricants, making it desirable for applications where particulate generation cannot be tolerated.

2019

A leaner, more modern Magnaplate

Magnaplate moves its headquarters and all processing to its Arlington, Texas facility and invests heavily in modern equipment to streamline processes and offer even better lead times.

Ashley Russo joins Magnaplate as Chief Operating Officer

Ashley becomes the third generation of our founding family to take a leadership role in the company, guiding Magnaplate through the COVID-19 pandemic and the Arlington facility expansion.

2020

Magnaplate achieves AS9100:D certification

The International Aerospace Quality Group issues the AS9100:D standard for companies to follow when establishing and maintaining a quality management system for doing business with the aerospace sector. You can view the certificate here.

2022

Magnaplate earns Nadcap accreditation for chemical processing

Nadcap accredits companies that provide special processes — such as coatings — and products for the aerospace industry. Accredited companies must undergo a series of audits conducted by the Performance Review Institute. You can see our Nadcap accreditation here.

2024

Ashley Russo becomes Chief Executive Officer

With Ashley Russo’s appointment, previous Magnaplate CEO, Candida C. Aversenti, becomes Chairman of the Board, and Edmund Aversenti will serve as President of the Board. In addition, Susan Neri becomes Magnaplate’s Chief Financial Officer (CFO), Ligon de Vogel becomes Chief Operating Officer (COO) and Nemanja Marinkovic becomes Chief Sales Officer (CSO).

2025

Celebrating our longtime colleagues

As a testament to Magnaplate’s strong commitment to excellence and employee well-being, these Magnaplate team members are celebrating long tenures of service:

35 years:

John Larsen, Wayne Cromwell, Corey Wesnitzer, Barry Wiedeman

40 years:

Michael McCreary, Valerie Corigliano, Susan Neri