Repair Coatings

Get the Most Utility Out of Your Old Parts

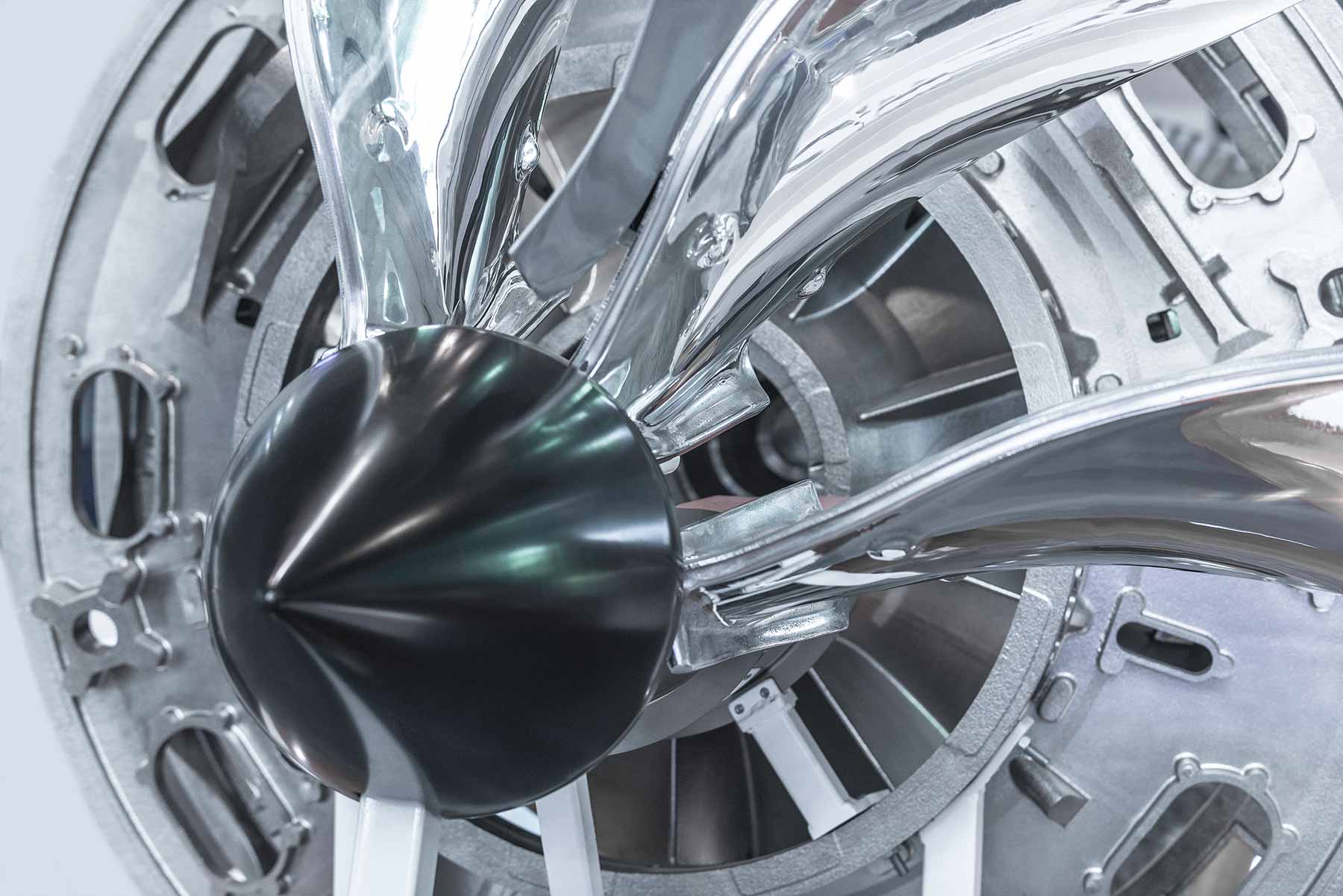

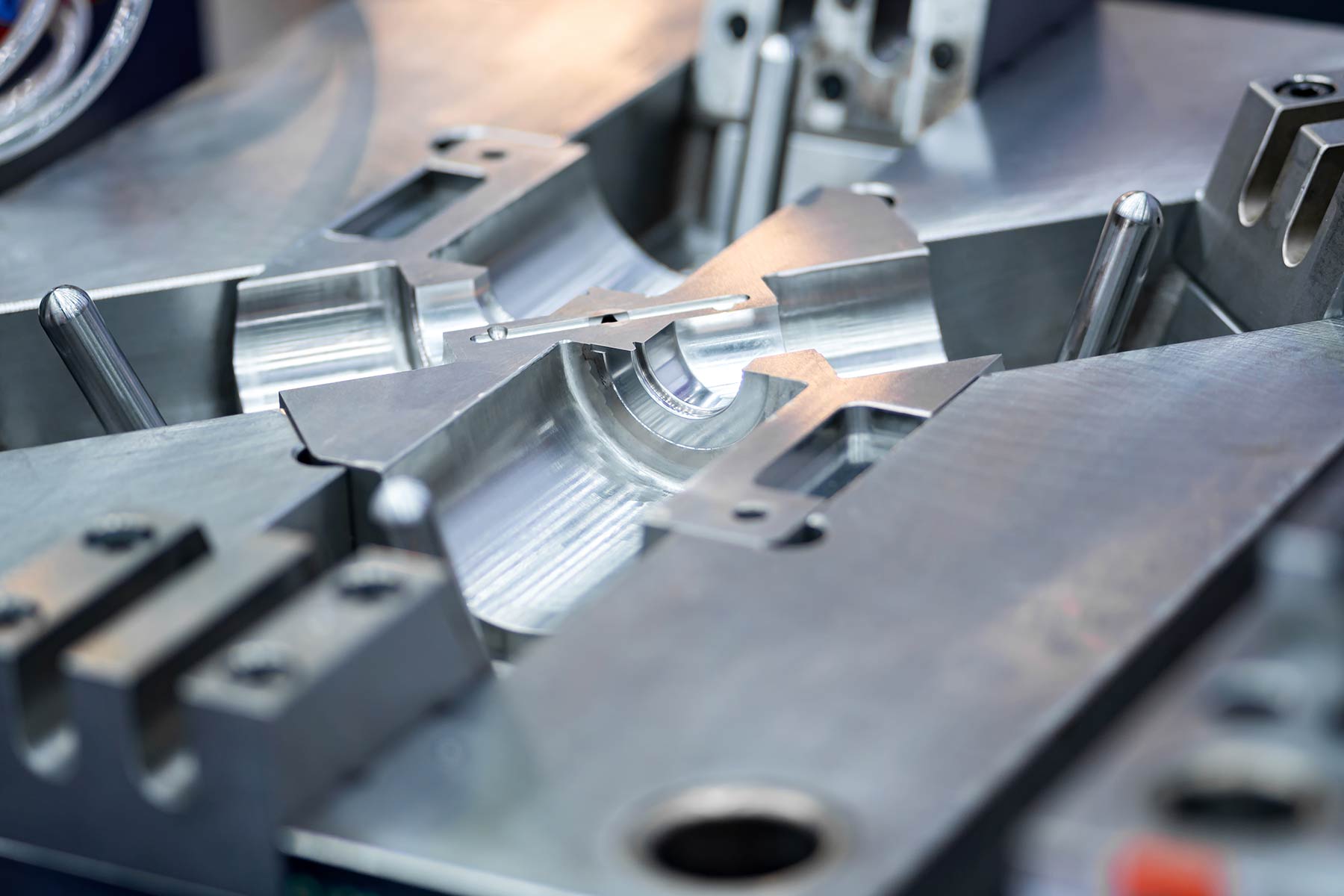

It’s no secret that our surface treatments effectively protect new parts against damaging conditions. They’re also well-suited for maintenance and repair efforts, delivering many benefits that can make restoration a more cost-conscious and sustainable option rather than part replacement.

Our coatings can add hardness, dry lubrication and chemical and corrosion resistance to your parts so they can achieve a longer, more productive lifetime in the field. If you need to repair or restore old parts, simply ship them to our facility. We'll recoat and refurbish your parts to last longer while saving money.

When you add our surface treatments to your maintenance, repair and operations (MRO) strategy, you’ll upgrade part surfaces and make better use of time and raw materials. The result: less downtime, better efficiency and more cost savings.

Give Old Parts New Life

Have parts that need repair or refurbishment? Our engineers can help you select the right coatings to make your parts run like new.

Request a QuoteIdeal Surface Treatments

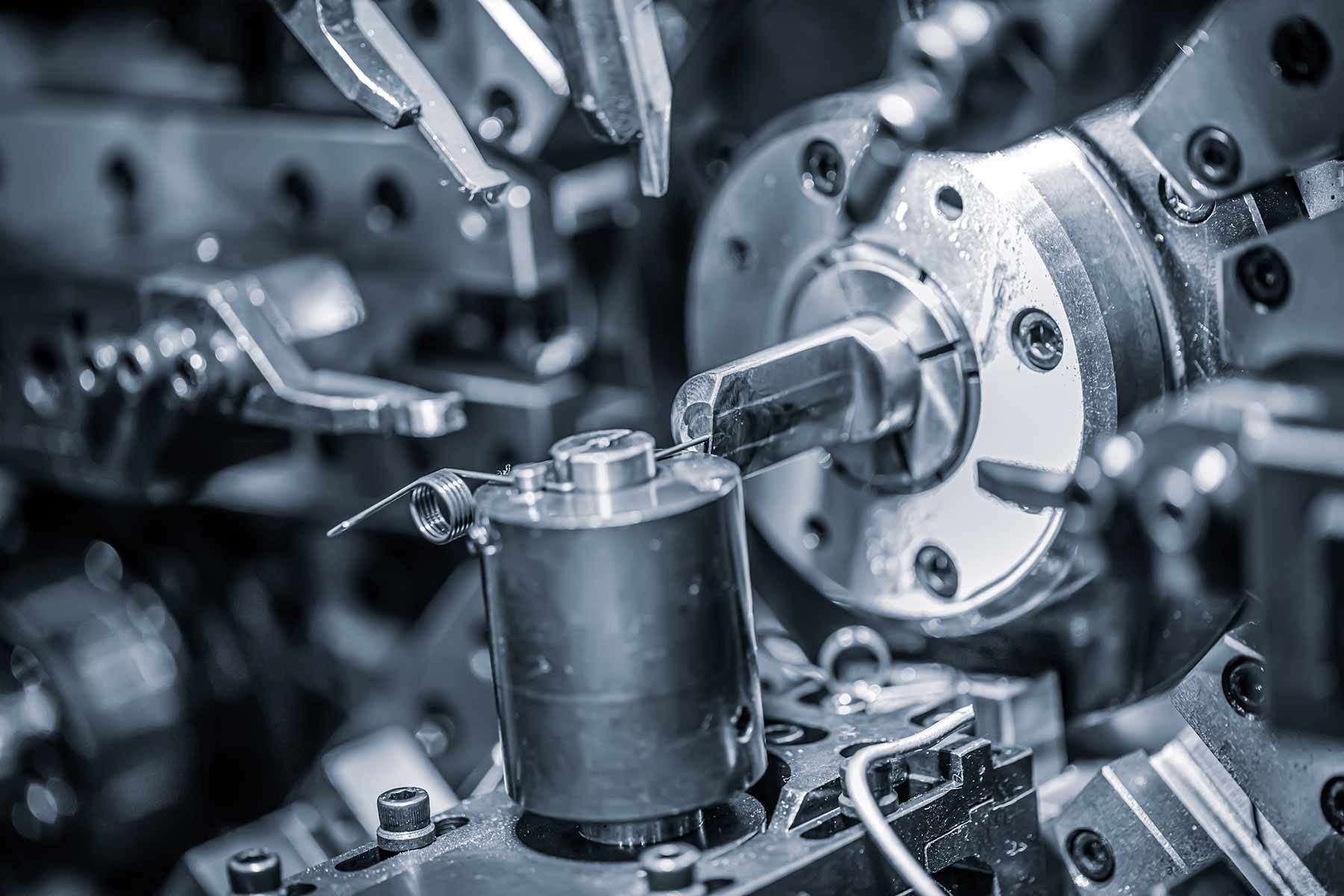

Nedox®

Electroless nickel coating provides superior protection against wear, friction and corrosion.

Capabilities

- Helps less-durable metals achieve the longevity and performance of chrome and stainless steel

- Eliminates stick-slip and enables easy cleanup

- Surface hardnesses up to Rc 68

- Chemical, acid and alkaline resistance

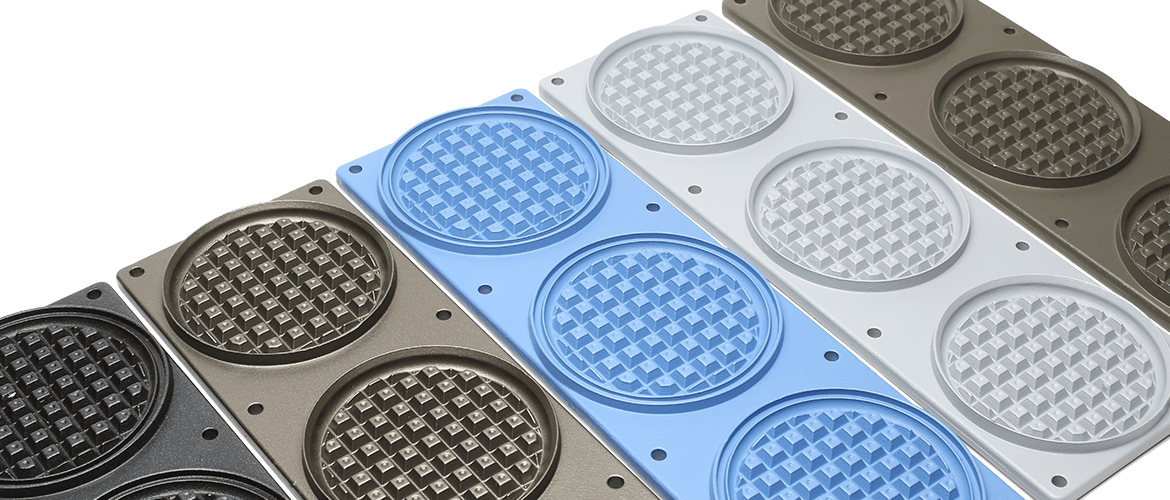

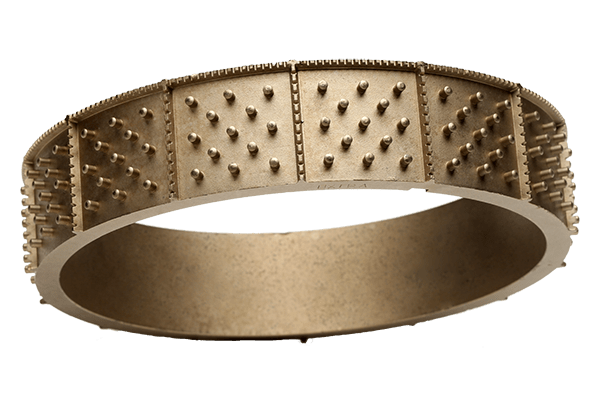

Tufram®

This hard anodizing coating protects aluminum and aluminum surfaces from corrosion and friction.

Capabilities

- Dramatically improves the surface hardness of aluminum

- Surface hardness between Rc 42 and Rc 50

- Self-lubricating and non-wetting surface characteristics

- Corrosion, abrasion and galling resistance