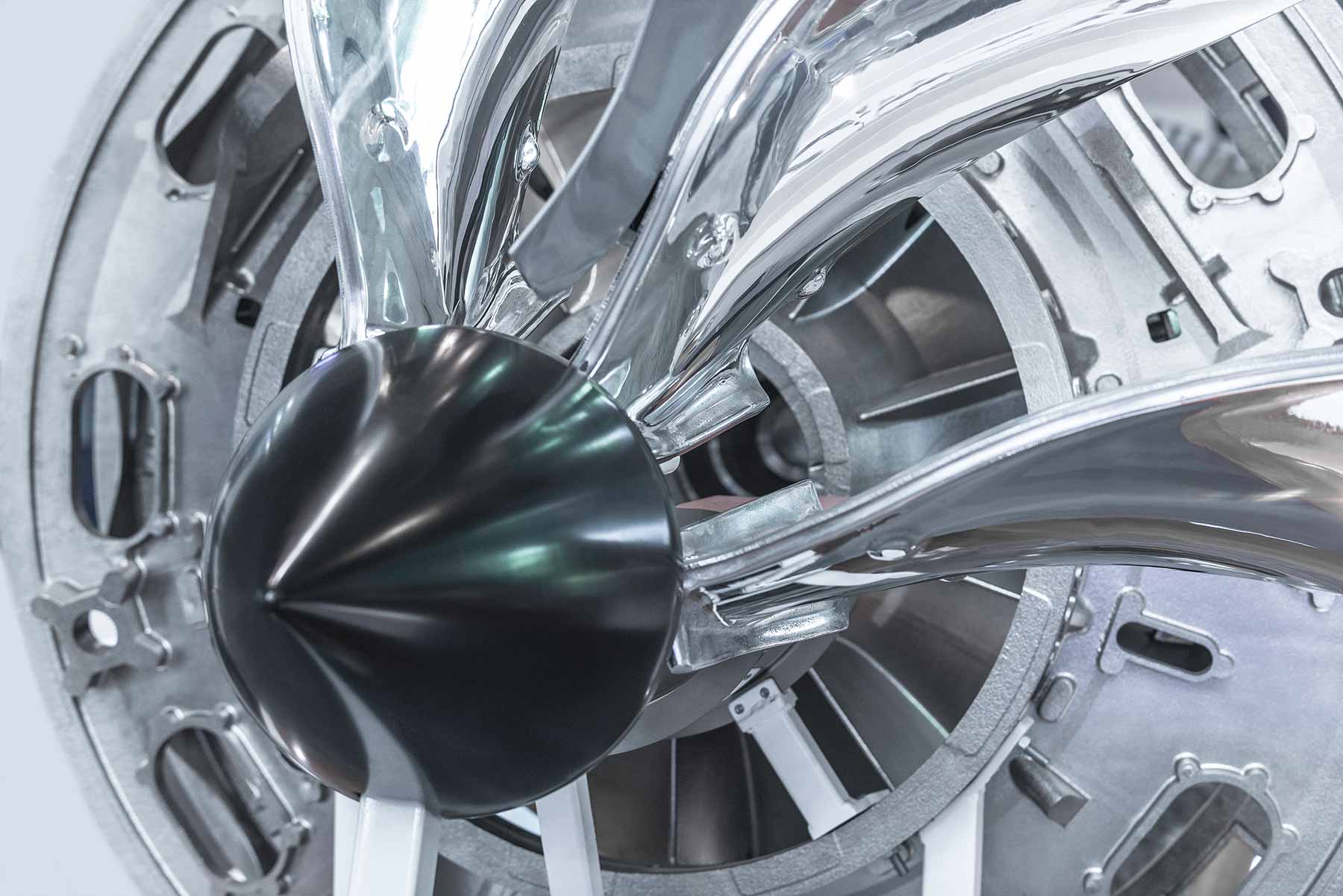

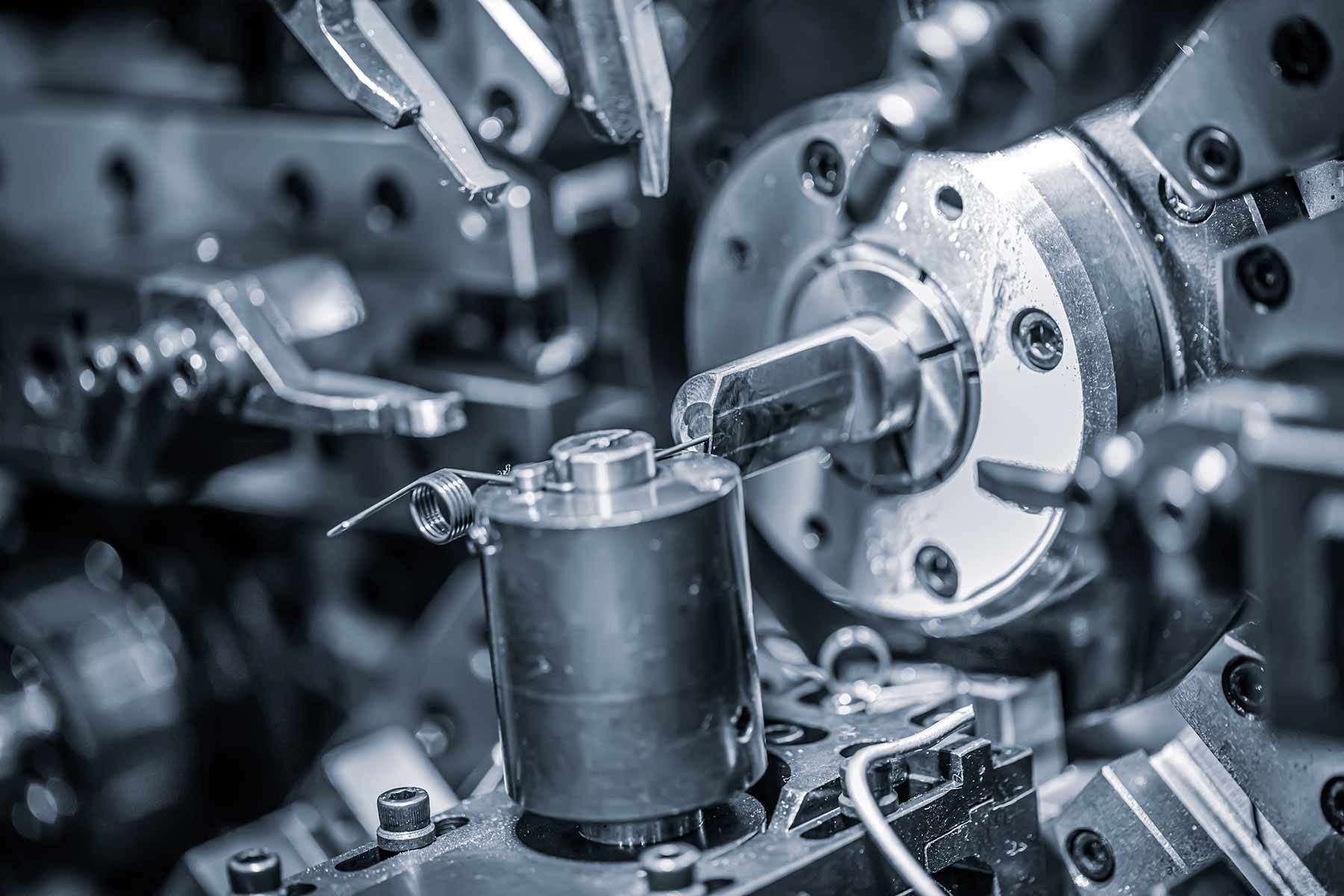

Wear Resistant Coatings

Machine Reliability and Long Lifetimes Start With Wear-Mitigating Surface Treatments

Protecting metal surfaces from conditions that lead to wear will ensure your parts perform reliably. Because part surfaces across many industries are susceptible to wear, it pays to partner with a surface treatment provider that can tailor the right coating to your application, avoiding wear before problems arise.

We engineered our surface treatments to deliver properties that keep coefficients of friction low to prevent sliding wear, protect parts from corrosion, and improve surface hardness to resist abrasion and galling. Simply bring us your application information and data, and we’ll recommend a coating capable of withstanding the various wear mechanisms that erode part reliability. The result: maximum productivity and long machine lifetimes.

Stop Wear in Its Tracks

Ready to put an end to wear? Our engineers are available to help you select the right coating for your application.

Request a QuoteIdeal Surface Treatments

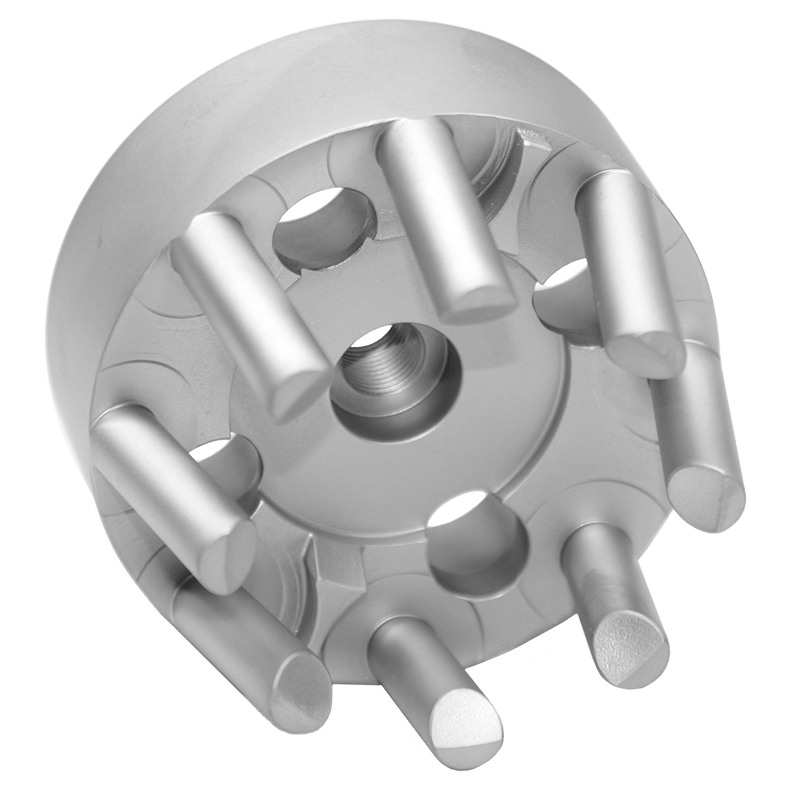

Dynaloy®

Friction-lowering hard anodizing composite for high-temperature applications

Capabilities

- Wear, abrasion, galling and corrosion protection

- Hardnesses greater than 67 Rc

- Uniform thicknesses from 0.0001 to 0.0003 inch

- Precise reproduction of substrate surface morphologies

- Resists most organic and inorganic compounds

Nedox®

Electroless nickel coating provides superior protection against wear, friction and corrosion.

Capabilities

- Helps less-durable metals achieve the longevity and performance of chrome and stainless steel

- Surface hardnesses up to Rc 68

- Eliminates stick-slip and enables easy cleanup

- Chemical, acid and alkaline resistance

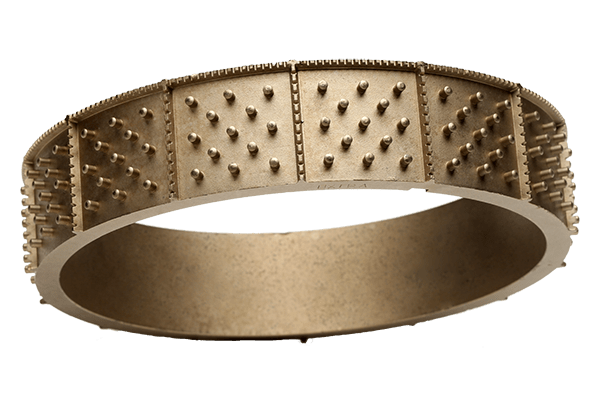

Tufram®

This hard anodizing surface treatment dramatically improves the surface hardness of aluminum versus other processes.

Capabilities

- Protects against abrasive wear mechanisms and galling

- Surface hardnesses between Rc 42 and Rc 50

- Low coefficient of friction (COF)

- Reduces stick-slip behavior and the resulting vibrations in sliding motion applications

- Replaces more expensive substrates