Proprietary Electroless Nickel Plating Processes Improve Part Performance and Durability

Nickel plating combines high strength and uniform deposition to enhance part durability and aesthetics. Treated parts resist corrosion, galling and wear, ensuring greater performance and long life under adverse conditions. Our proprietary processes create coatings that can outperform many common nickel-based plating technologies and provide surface enhancements that are superior to chrome and stainless steel.

Choose from a variety of processes and coating constructions. For example, our Nedox® electroless nickel plating family includes a ceramic composition for applications that may not tolerate polymers and dry lubricants. Magnaplate HMF® is based on a multi-step process that creates slippery surfaces with very low friction, and Hi-T-Lube® leverages patented matrix construction for exceptional performance under severe conditions.

Applications and Industries

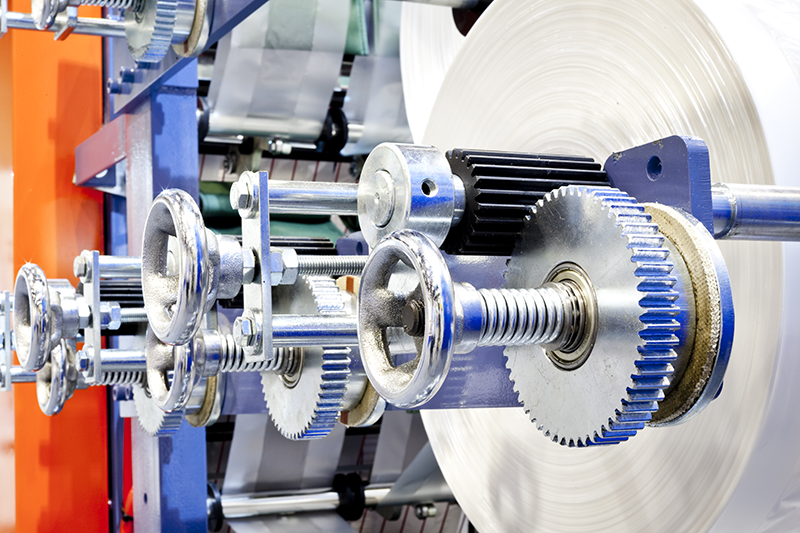

Nickel plating is well-proven in diverse applications and industries including guided missile system and aircraft support equipment in aerospace, robot gears and bearings for automated manufacturing, tablet presses and diagnostic equipment in the pharmaceutical and medical industries, oil and gas installations, chemical processing, food and beverage processing and paper and packaging equipment.

Our experts can review your requirements and explain the properties of our nickel plating options to help you select the best approach.

Advantages

Good corrosion resistance

Excellent friction-lowering properties

Wear, abrasion and galling resistance

Good sliding and release properties

Uniform thicknesses

Hardness up to 68 Rc

Wide operating temperature ranges

Nedox’s 22 x 2.9 x 2.5-foot tanks exceed industry standards and can handle much larger parts than competitors

FDA- and USDA-compliant coatings are available

Compliance with material standards such as AMS 2404, AMS-C-26074, B-733, and REACH

REACH compliance

Ideal Surface Treatments

Is a Nickel Coating Right for Your Application?

Our engineers are ready to help you select and customize the best nickel-based surface treatment for your application.

Contact UsTechnical Resources

Videos

Webinars

White Papers

Engineered Coatings Boost Throughput, Solve Problems in Packaging Applications

Keeping packaging equipment up and running is top priority for engineers and plant personnel. Faced with ever-increasing productivity benchmarks based on fast and efficient operation, packaging engineers must continually fight against issues such as sticking, premature wear, abrasion and corrosion. To eliminate these challenges, nano-engineered coatings are being used to protect machine components and solve performance problems in food, pharmaceutical and consumer goods packaging.

Case Studies

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.

Blog Posts

Plasmadize® Puts the Chill on Sticky Metal Chutes for Ice Pop Maker

The food industry — particularly producers that use sticky ingredients — can trust Magnaplate coatings to maintain machine performance and ensure product quality.