Coatings Technology Blog

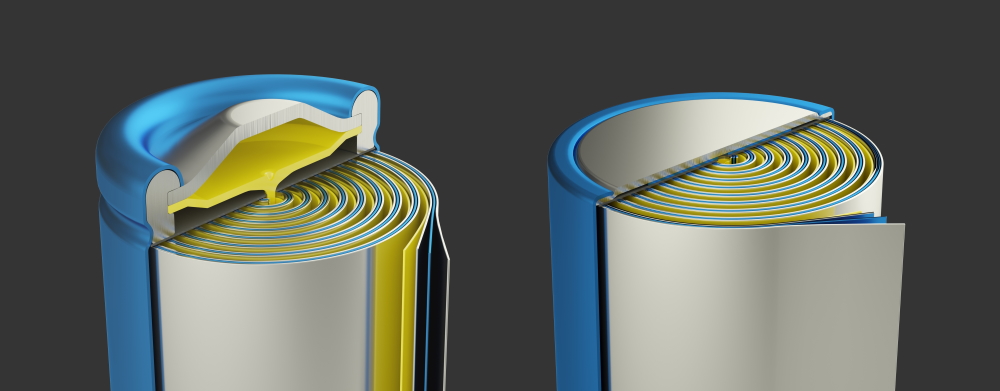

A Nedox Coating Keeps Battery Powders Pure

When handling raw powders is your stock in trade, you will no doubt be concerned about the effects of abrasion on your equipment. Not only can abrasion damage the vessels, it can in turn contaminate the powders they hold and cause problems down the line. For example, batteries used in the automotive and aviation industries rely on pure lithium. Even the slightest impurity can affect their performance and reliability.

A Magnaplate customer that refines lithium and other critical metals for battery production received reports indicating that its battery material purity was compromised by abrasion to the stainless steel tubing — supplied by its customer and used to transport the powders. This is unacceptable, because contaminated lithium can cause a short in the battery and dramatically reduce battery performance, reliability and lifetime.

After consulting with Magnaplate, the company began using one of our Nedox® coatings on the steel tubing components for greater abrasion resistance and, in turn, to prevent contamination of the refined product. Nedox, based on the electroless nickel process, effectively protects against wear, friction and corrosion, helping less-durable metals achieve the longevity and performance of chrome and stainless steel. The type of Nedox used features hardness up to Rc 65, combined with lubricity and release.

Additional benefits include:

- Chemical, acid and alkaline resistance.

- Good electrical properties, such as a low dissipation factor and high resistivity.

- Low thermal conductivity.

- Low coefficient of friction to prevent caking and cascading of powders.

This engineered Nedox coating dramatically improved the service life of the stainless steel tubing thanks to its extreme hardness and dielectric polymer seal.

Take Charge of Preventing Powder Contamination

Nedox eliminated the contamination problems for the end customer when producing the refined stock. With these results, the powder and bulk solids industry can trust Magnaplate engineered coatings to improve and ensure product purity.

For more information about Nedox coatings, visit our product page.