Coatings Technology Blog

Canadize® Prevents Hydrogen Absorption For Titanium

Titanium is often susceptible to hydrogen pickup or embrittlement. For applications that experience this issue, we’ve created a coating that focuses on preventing hydrogen absorption.

Better Than Titanium Anodizing. Our Canadize® coating lowers the coefficient of friction of titanium substrates and prevents hydrogen embrittlement. When compared to other common industry processes like titanium anodizing, this coating has better technical features, including:

- An operating temperature range from -200 to 1200°F

- Coating thicknesses from 0.0001 to 0.0006 inches

- A hardness of Rc 45

- AMS 2488 requirements

- Excellent heat transfer

- High fatigue strength

- Chemical and corrosion protection

Surfaces coated with Canadize® can successfully solve wear, friction, galling, seizing, moisture and corrosion problems in a broad spectrum of applications involving titanium and its alloys. Through predetermined time and current control, a hard ceramic surface is formed.

Application Examples. Canadize® has been successfully applied to applications in aerospace, manufacturing and packaging equipment, construction, power tool applications. Here are two examples of times when this coating solved engineering problems:

- A variety of metal parts used in the manufacture of sealed reagent kits for chemical testing were coated with Canadize® to provide chemical resistance and increase the service life of the manufacturing equipment.

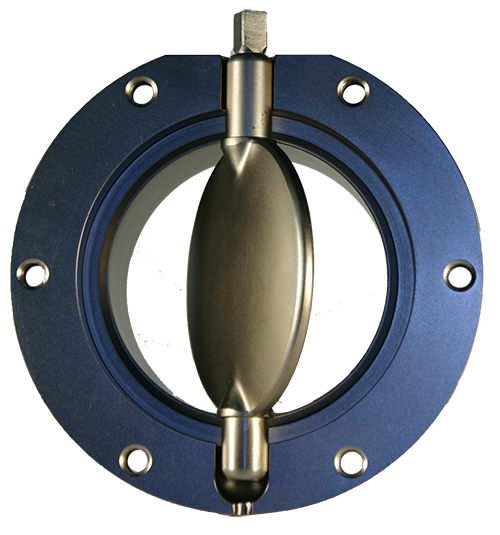

- Galling and seizing compromised valves in pressure vessels and piping systems controlling the flow of LP gas and anhydrous ammonia. With its anti-galling and anti- seizing properties, our Canadize® coatings solved the problem and eliminated a potentially dangerous situation.