Coatings Technology Blog

Prevent a Hot Mess - How Our CS-1331 Coatings Wipe Away PVC Residue

Polyvinyl chloride (PVC) is known for its versatility, but you don’t want to get it on your metal parts. This widely used plastic is highly abrasive and, if it builds up on machine surfaces, can cause wear. That’s why it’s important to be vigilant about preventing residue from forming on machine parts that make contact with PVC plastic. To mitigate the effects of PVC residue, you can look for a coating with stick-release properties. However, it can be hard to find a surface treatment that releases PVC effectively at the high temperatures that cause PVC sticking.

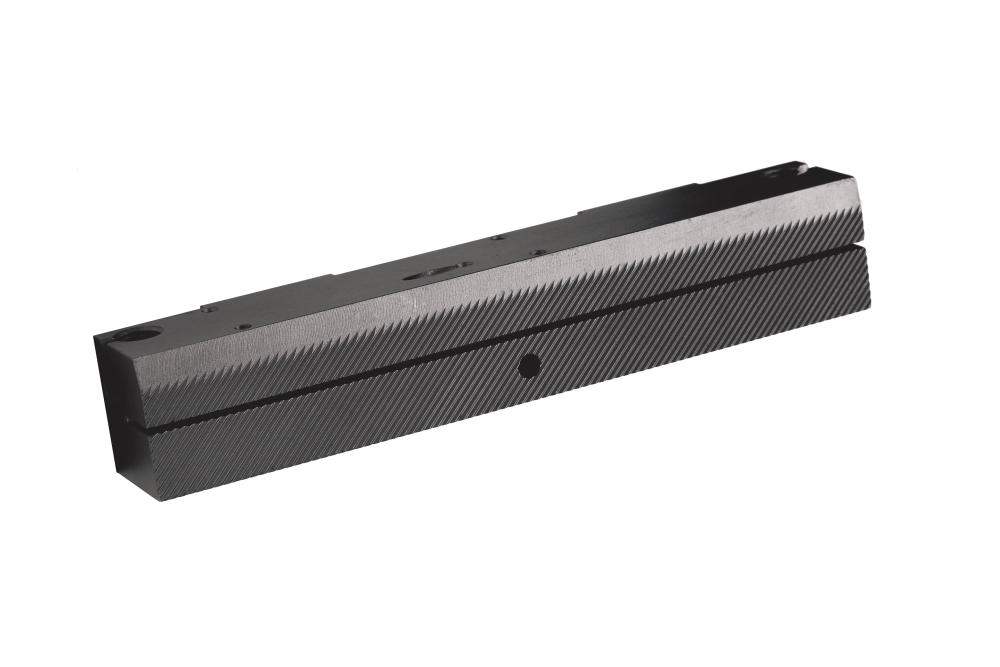

At Magnaplate, we have a lubricious coating type that not only offers PVC release properties, but also has proven thermal stability up to 500°F. We formulated CS-1331, available as part of our Lectrofluor® and Plasmadize® surface treatment families, to deliver exceptional non-stick properties and wear resistance to PVC for many applications. By solving PVC sticking and wear, CS-1331 can reduce the downtime and expenses caused by these issues.

In repeated testing at 500°F, CS-1331 released the PVC plastic during cleaning without applying much pressure — using a simple rag — at different areas of the treated surface. It also outperformed other non-stick release coatings at the elevated temperature.

CS-1331’s advantages include:

- Corrosion resistance. CS-1331 was tested in accordance with ASTM B117 and provided up to 336 hours of salt spray resistance.

- Outgassing and chemical resistance. In addition to residue issues, PVC can outgas at certain temperatures, releasing acids that can cause pitting or oxidation for machines. CS-1331 offers exceptional protection against outgassing, as well as great resistance to a wide array of chemicals and cleaners.

- Low coefficient of friction (COF). ASTM D 1894-01 testing results indicated a static COF of 0.11 and kinetic COF of 0.09.

- High contact angle. Contact angle indicates the surface energy present on a coated surface. During testing, CS-1331 exhibited a contact angle of 106.6 degrees. In general, a contact angle above 100 degrees allows better release and surface cleaning.

- USDA and FDA compliance. CS-1331 is suitable for applications involving food and pharmaceutical contact.

Both our Lectrofluor® and Plasmadize® families offer the CS-1331 composition. Here are their ideal use cases:

- Lectrofluor®. This polymer matrix coating is well-suited for harsh environments.

- Plasmadize®. Using an enhanced thermal spraying technique, this cost-effective surface treatment produces a ductile coating that creates a wear-resistant and non-stick surface. Plasmadize is particularly useful for very large surfaces or parts.

Easy PVC Cleanup

When it comes to PVC residue, you can’t afford to experiment with the wrong surface treatment. Our CS-1331 coatings release PVC plastic at elevated temperatures, making cleanup easy and preventing wear and abrasion for greater machine runtime and far less downtime.

For more information about Lectrofluor- or Plasmadize-CS1331 surface treatments for PVC release, contact us.