Coatings Technology Blog

Protect Your Pumps With Engineered Coatings

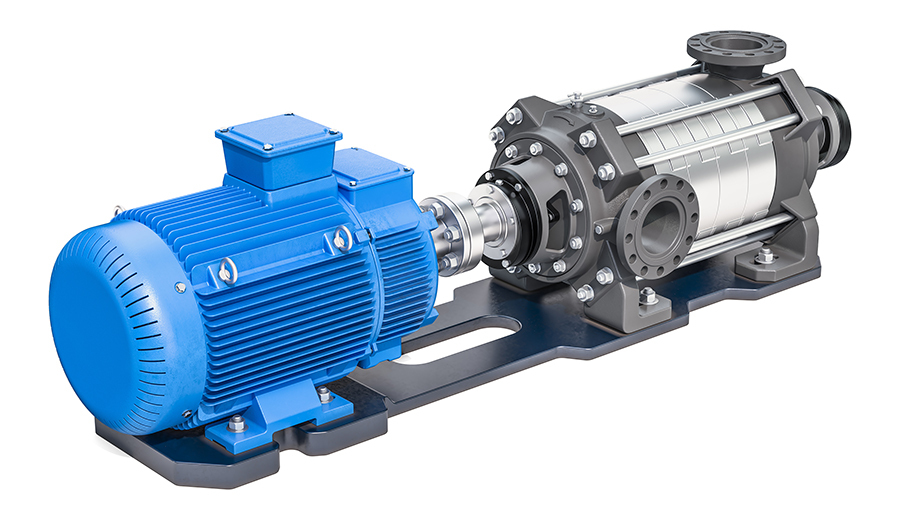

Pumps are subjected to a host of threats that can impact their reliability and your operation’s productivity. Surface-enhancement coatings are a wise choice to protect pump surfaces, but choosing the right coating is anything but straightforward. You must consider many factors, including the base metal of your pump, its operating environment and the materials it will encounter. That’s why it pays to work with a coatings provider that engineers its coatings to address your application’s specific requirements and resolve any issues you are experiencing with your pumps.

Magnaplate coatings have decades of proven success protecting pumps in various conditions. They are specially designed to protect against wear, abrasion, galling and corrosion — common threats to pump impellers, wear plates, housings and other vital parts. Our coatings give ordinary metal and alloy surfaces corrosion-resistant, super-hard and dry-lubricated properties for superior performance and reliability. At Magnaplate, we can engineer the right coating with these value-added benefits in order to:

- Protect a specific base metal or alloy.

- Address pH conditions and protect against acids.

- Handle solid materials that contact pump parts.

- Achieve specific coating thicknesses and tolerances.

- Perform in extreme high temperatures.

With Magnaplate engineered coatings, pumps achieve optimal material flow while maintaining system uptime and productivity. In fact, you’ll find our coatings protecting many types of pumps from threats across many industries. Examples include:

- Wear, cavitation wear, abrasion and corrosion in oil and gas applications.

- Corrosion, wear and abrasion in dairy and food processing. Coatings can also protect against food material buildup and sticking in various pump configurations.

- Corrosion in municipal water facilities.

- Wear in piston pumps used with heavy equipment and machines.

- Harsh chemicals, acids and pH in centrifugal, piston or gear pumps.

Many Magnaplate coatings are particularly suited for certain base alloys. For example, most cast or ductile irons, steel and stainless steels can be treated with Nedox®, Plasmadize® or Lectrofluor® coatings. For aluminum housings and piston shafts, consider Tufram®. Our team can examine your project’s details such as base metals and the pH ranges your pump will encounter. Be sure to identify all problems so we can work with you to select the best coating for the job.

Engineered Coatings Optimize Flow and Maximize Uptime

Engineered coatings are tailor-made for your pump’s environment and the surface’s specific base alloy and mechanical requirements so you can be sure it will stand up to corrosion, abrasion, wear, material buildup and various other conditions. That means optimal media flow and maximum uptime for your systems and equipment.